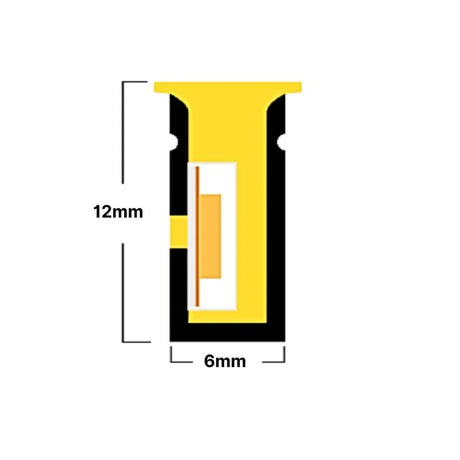

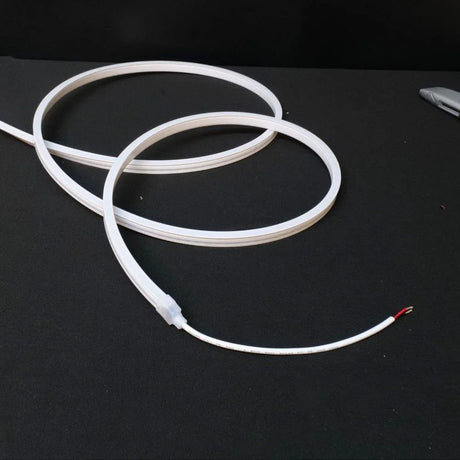

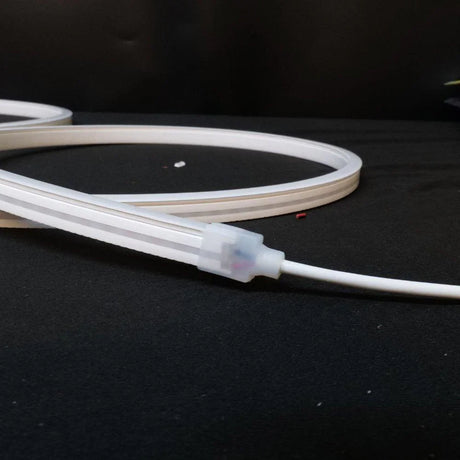

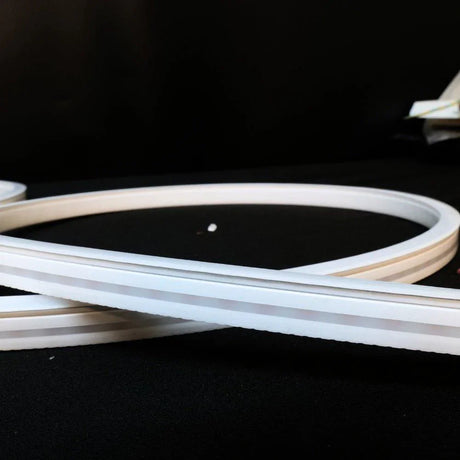

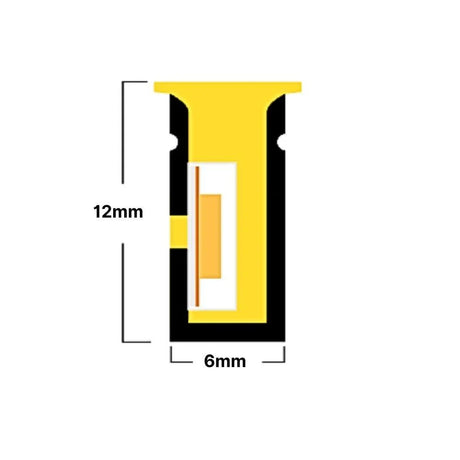

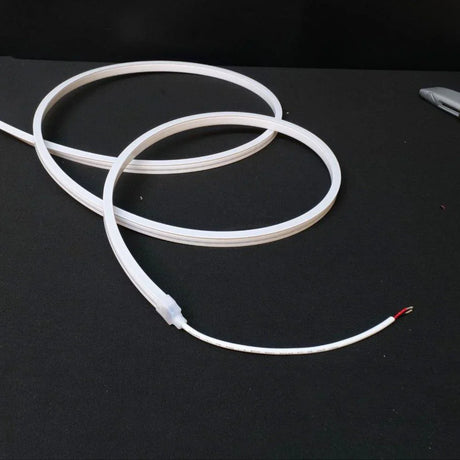

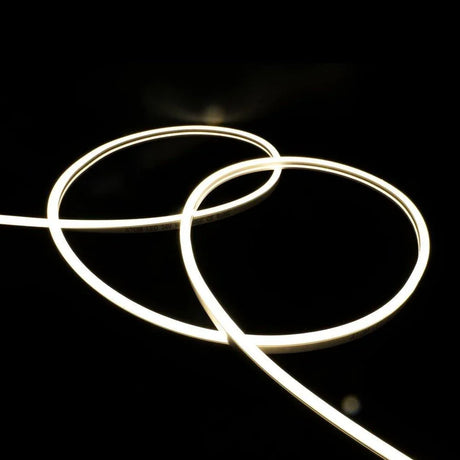

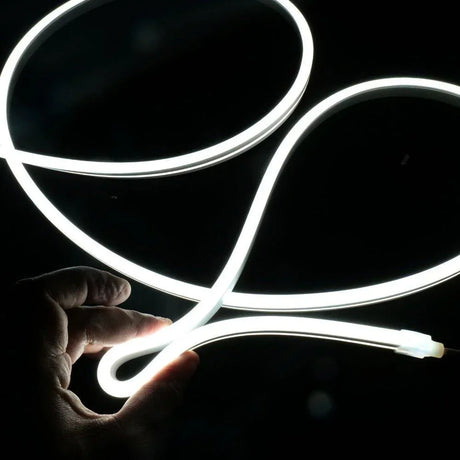

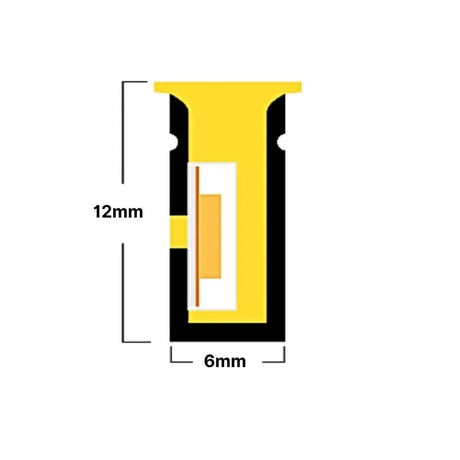

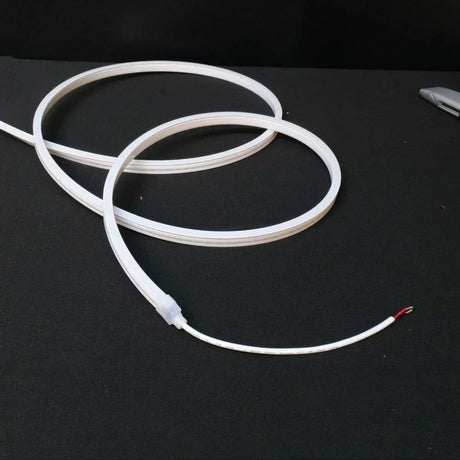

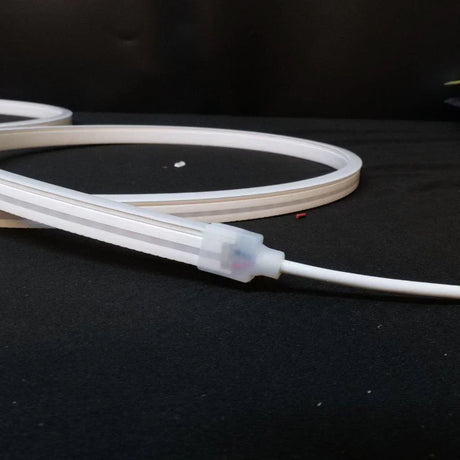

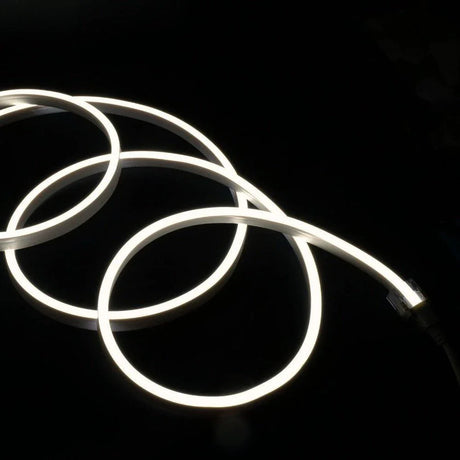

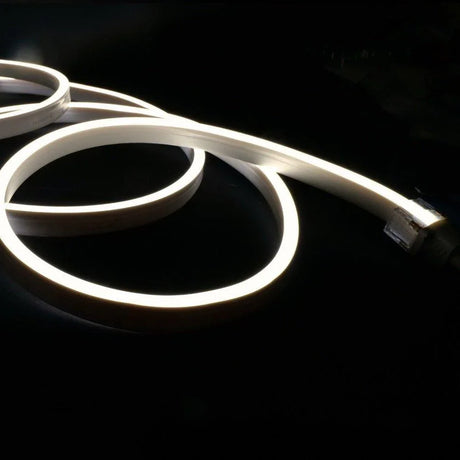

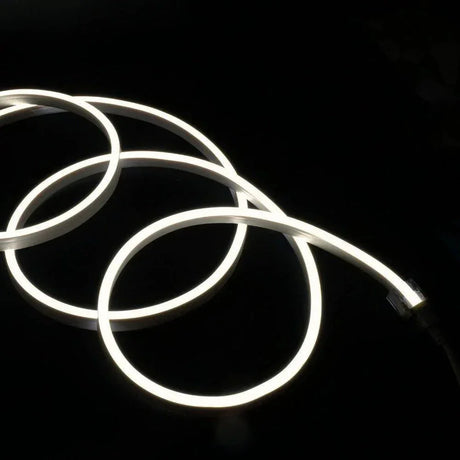

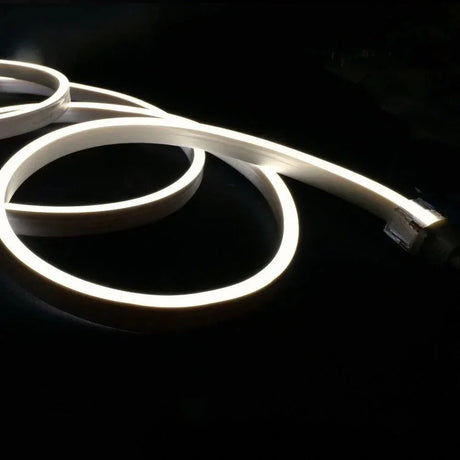

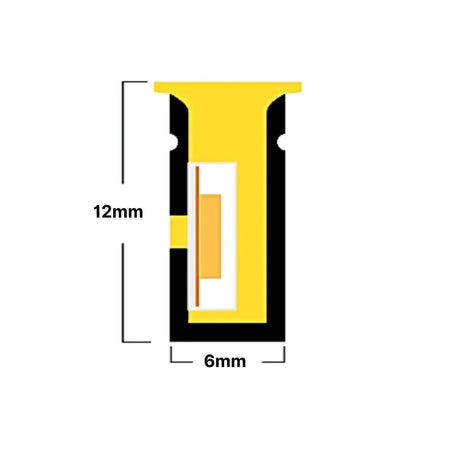

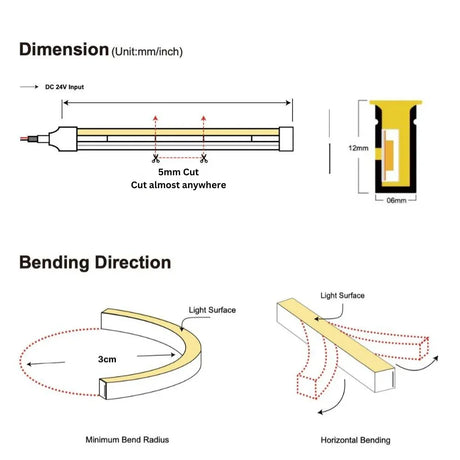

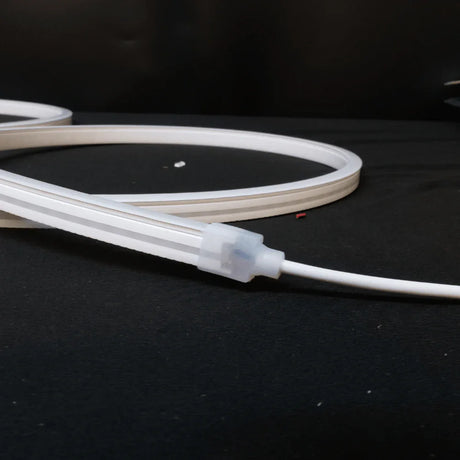

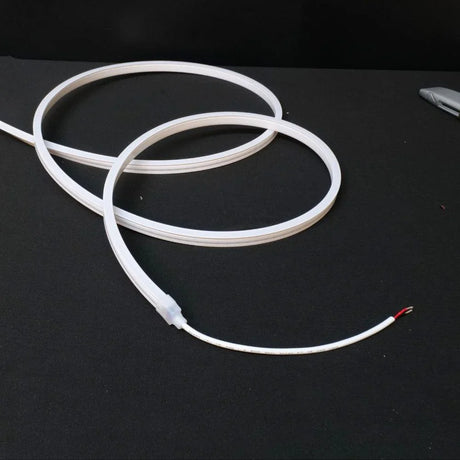

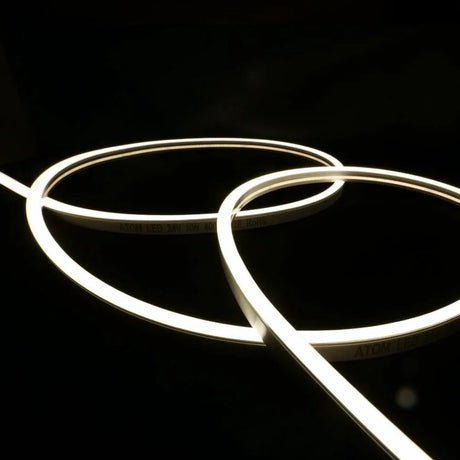

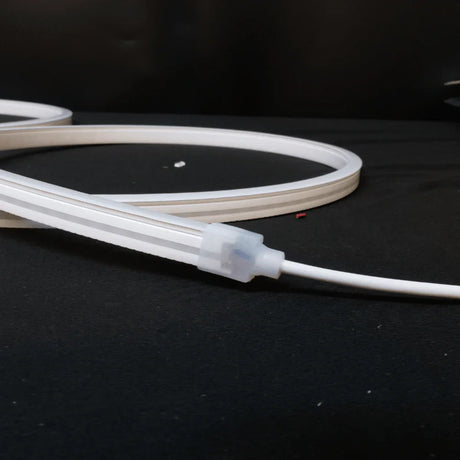

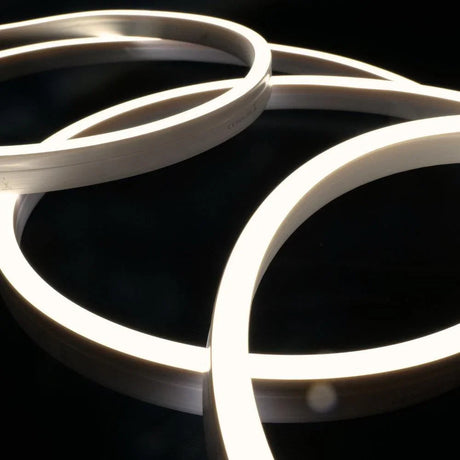

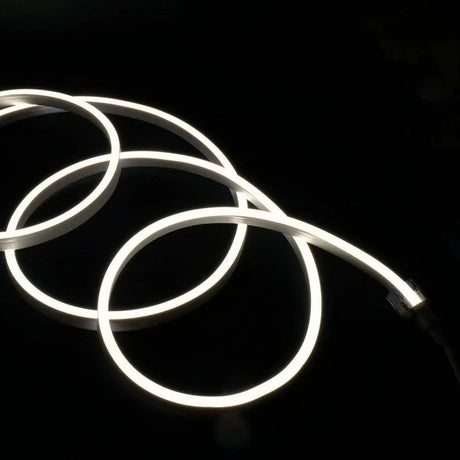

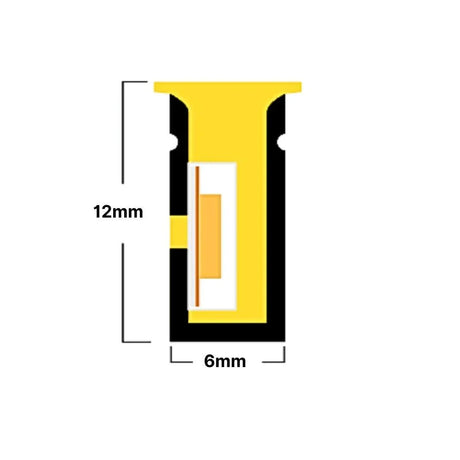

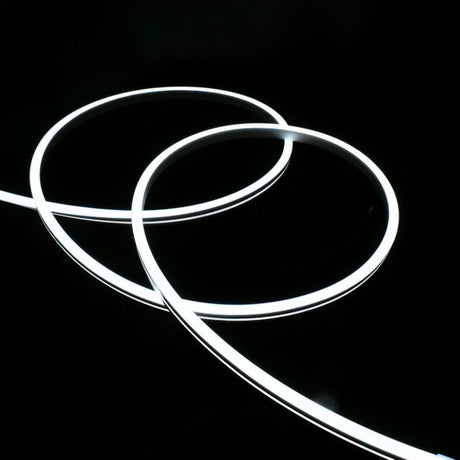

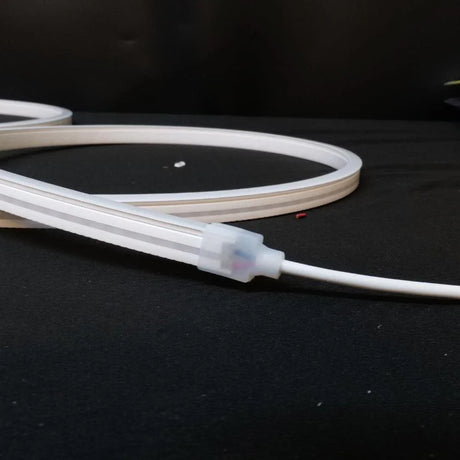

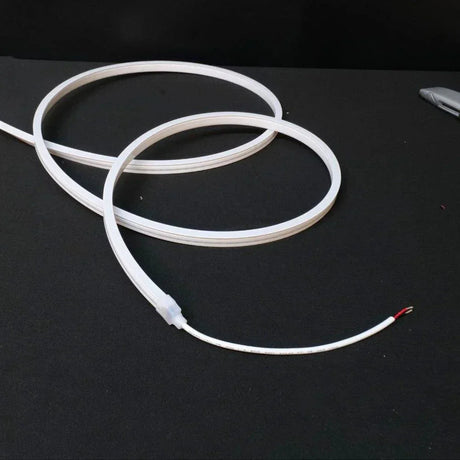

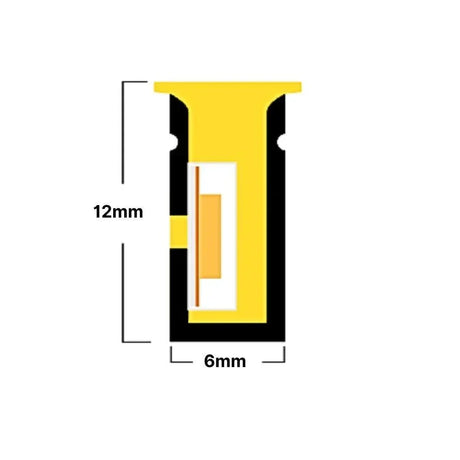

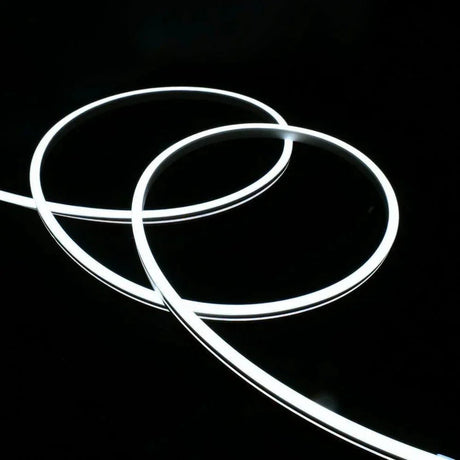

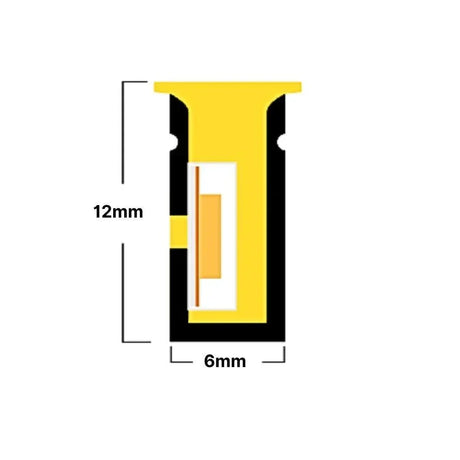

Natural White Neon Flex 4000K 24V 6x12mm IP67 Waterproof Free Cut

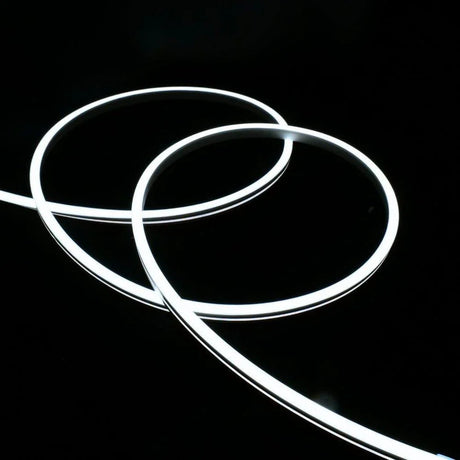

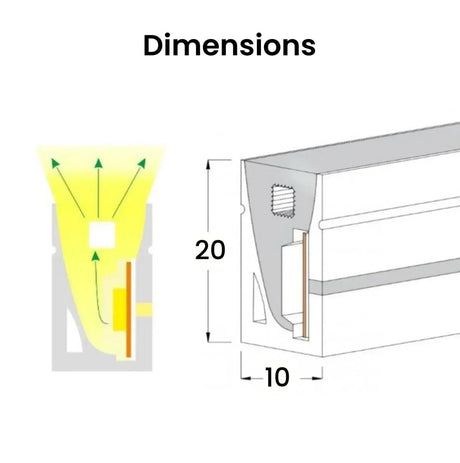

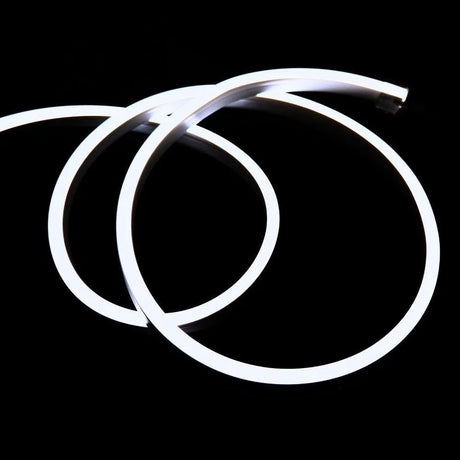

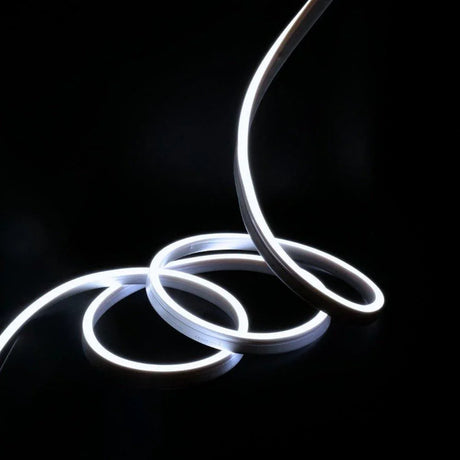

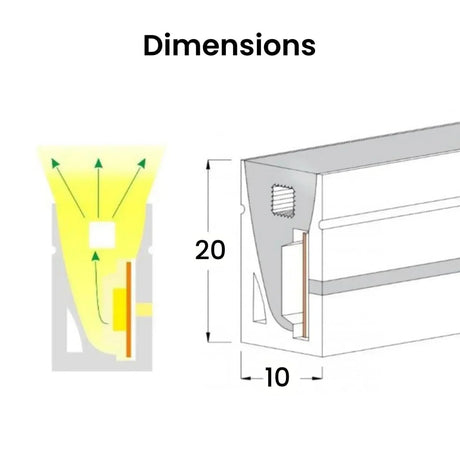

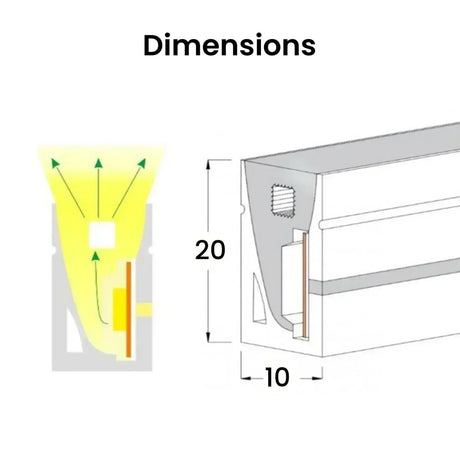

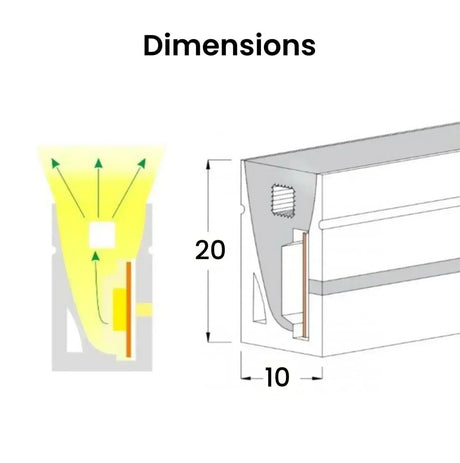

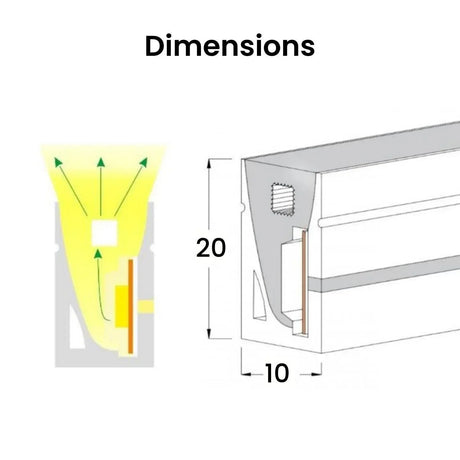

From £19.85Unit price /UnavailableCool White Neon Flex 6000K 24V 10x20mm IP67 Waterproof 20m

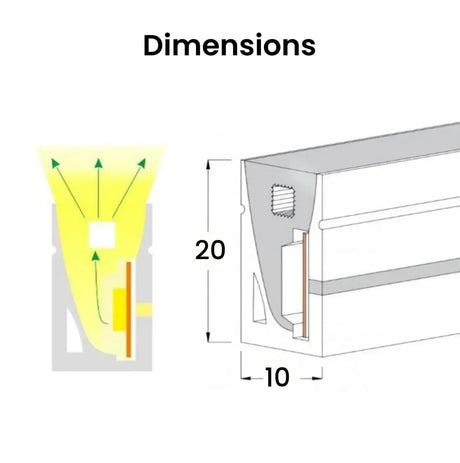

From £21.85Unit price /UnavailableNatural White Neon Flex 4000K 24V 10x20mm IP67 Waterproof 12.5cm Cut

From £21.85Unit price /UnavailableWarm White Neon Flex 2800K 24V 10x20mm IP67 Waterproof 20m

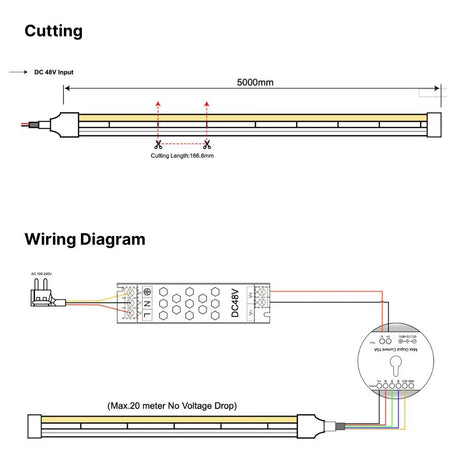

From £21.85Unit price /UnavailableNatural White Neon Flex 4000K 48V 10x20mm IP67 Waterproof 50m

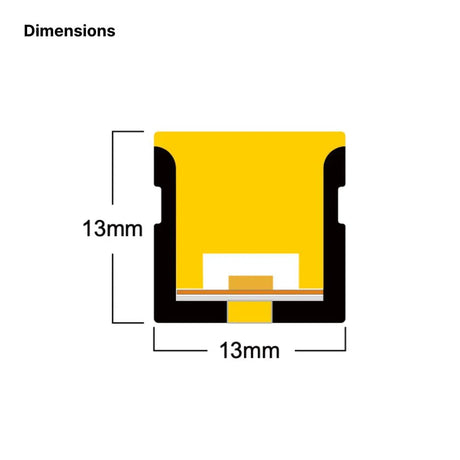

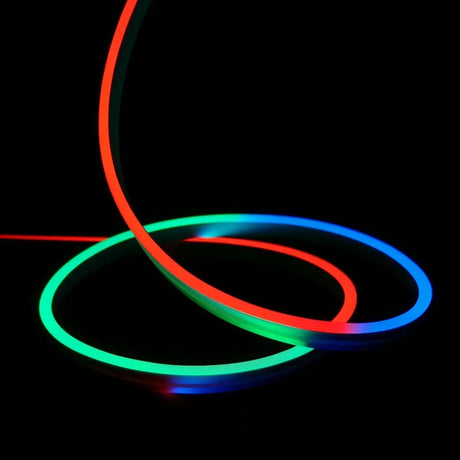

From £21.85Unit price /UnavailableRGBW (3000K) LED Neon Flex 13x13mm IP67 Waterproof 48V 20 Metre

From £21.95Unit price /UnavailableWarm White Neon Flex 2800K 48V 10x20mm IP67 Waterproof 50m

From £21.85Unit price /UnavailableDecking LED Light Warm White Neon Flex 2700K 24V 6x12mm IP67 Waterproof Cut Anywhere

From £19.85Unit price /UnavailableDecking LED Light Warm White Neon Flex 3000K 24V 6x12mm IP67 Waterproof

From £19.85Unit price /UnavailableDecking LED Light Natural White Neon Flex 4000K 24V 6x12mm IP67 Waterproof Cut Anywhere

From £19.85Unit price /UnavailableDecking LED Light Cool White Neon Flex 6000K 24V 6x12mm IP67 Waterproof Cut Anywhere

From £19.85Unit price /Unavailable

What are the key differences between PET and IP67 neon flex?

PET neon flex is lightweight and typically intended for indoor or protected locations, while IP67 neon flex is fully sealed against dust and temporary immersion and is built for outdoor exposure and harsher environments.

What does an IP67 rating mean for neon flex in real-world outdoor and wet use?

IP67 indicates total protection from dust and resistance to temporary immersion up to 1 metre, so properly terminated IP67 neon flex can handle rain, splashes, and occasional submersion when installed correctly.

How does IP67 compare with IP65 and IP68 in protection, cost, and typical use cases?

IP65 protects against jets/splashes (good for sheltered exteriors), IP67 adds temporary immersion resistance for more exposed outdoor use, and IP68 is for continuous submersion higher ratings generally increase cost and require more robust termination techniques.

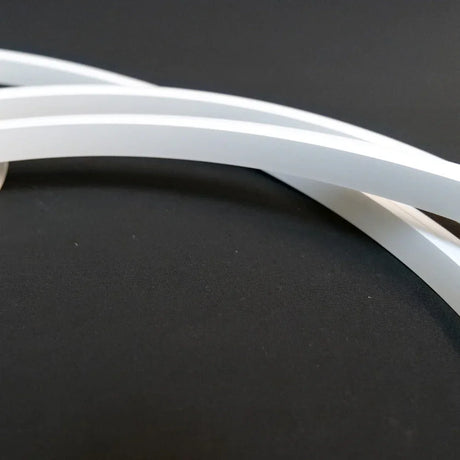

How do PET, PVC, PU and silicone neon flex compare in durability and weather resistance?

Silicone offers the best UV, temperature and chemical resistance for long-term outdoor use, PVC and PU are mid-range options with moderate durability, and PET is usually for indoor/light-duty applications.

What mounting methods are recommended for IP67 neon flex outdoors?

Use aluminum mounting channels, stainless steel clips, or UV-rated silicone adhesives with appropriate spacing for thermal expansion and mechanical strain relief to ensure a durable outdoor installation.

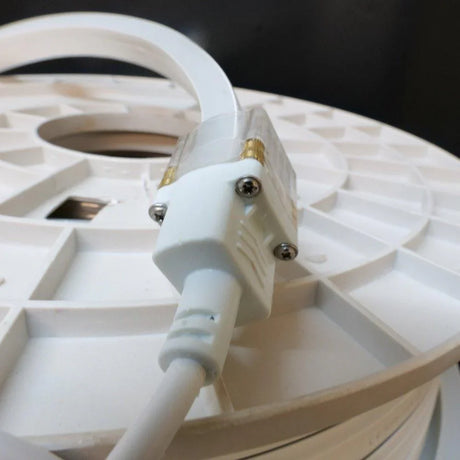

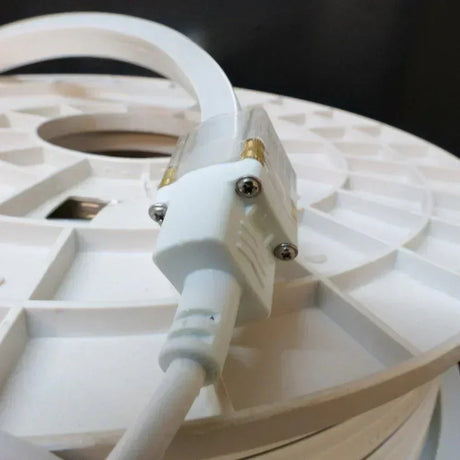

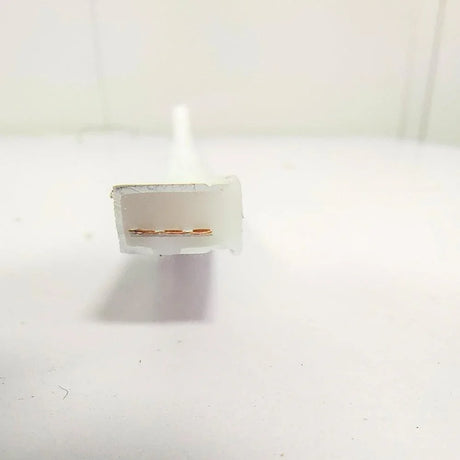

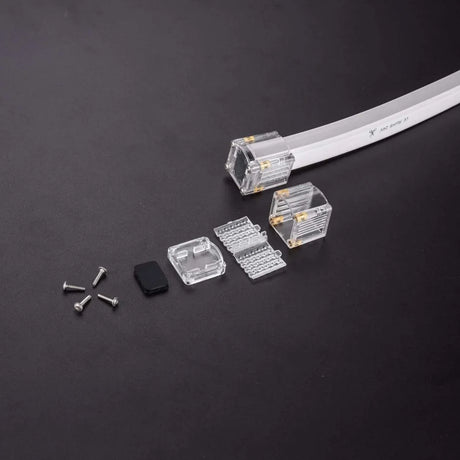

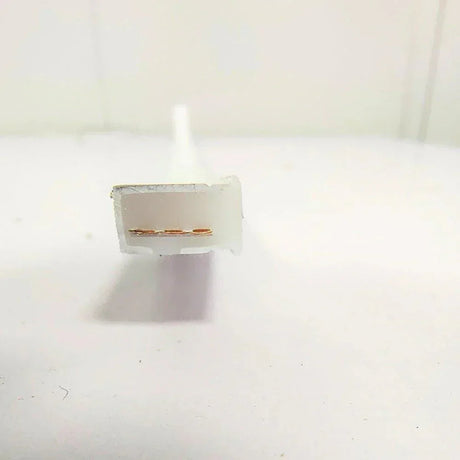

How do you splice and waterproof IP67 neon flex connections?

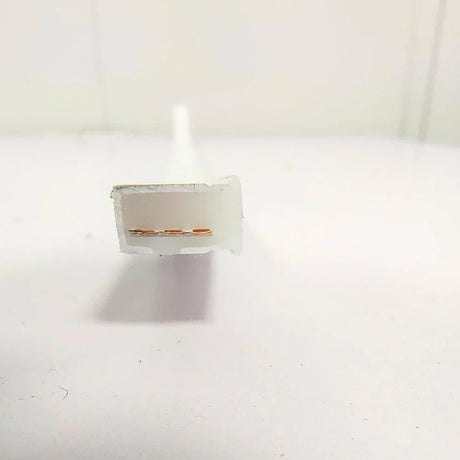

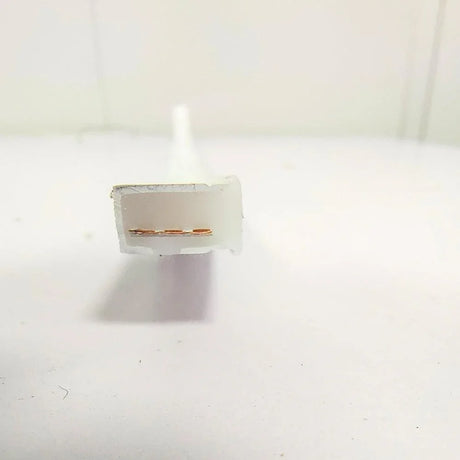

Use manufacturer-approved IP67 waterproof connectors or adhesive-lined heat shrink, then pot or seal the joint with neutral-cure silicone or resin to restore the enclosure and prevent moisture ingress.

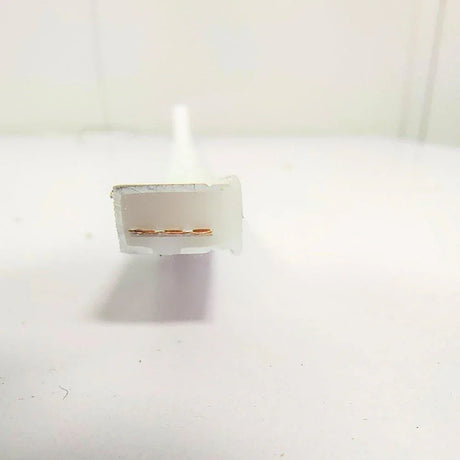

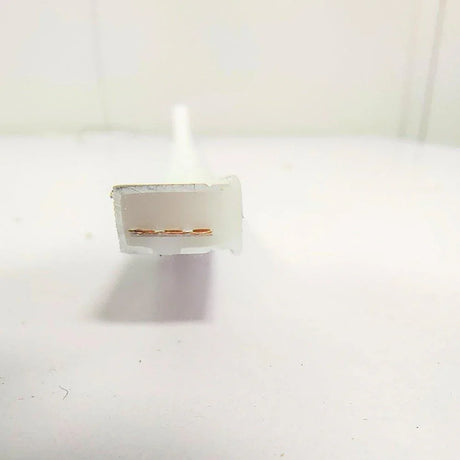

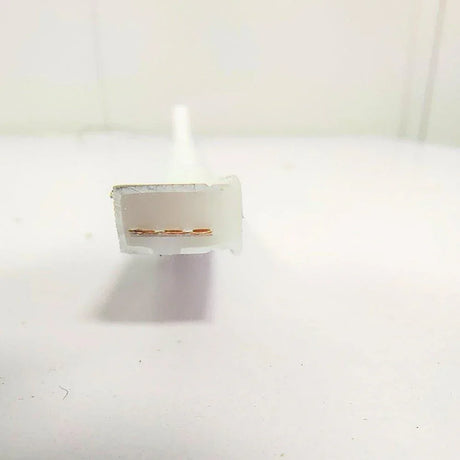

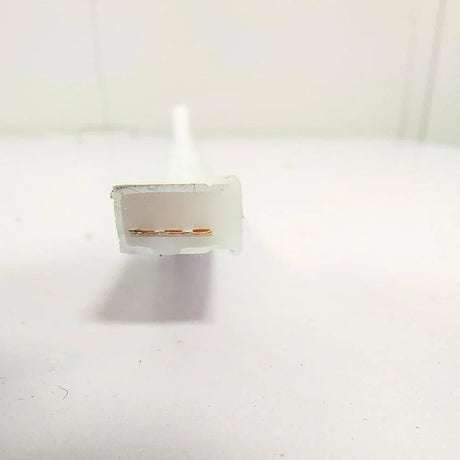

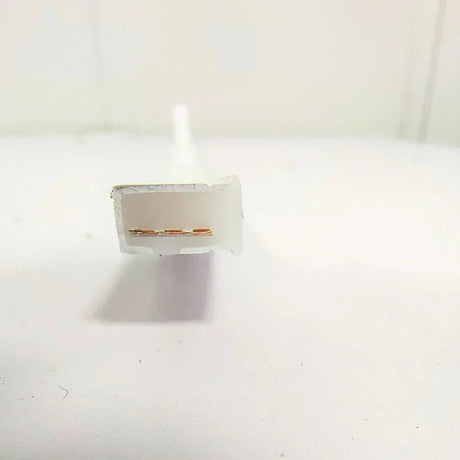

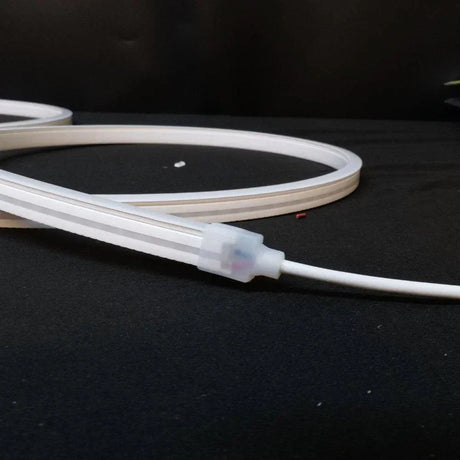

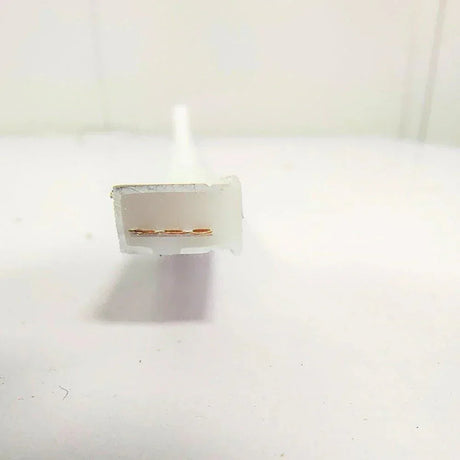

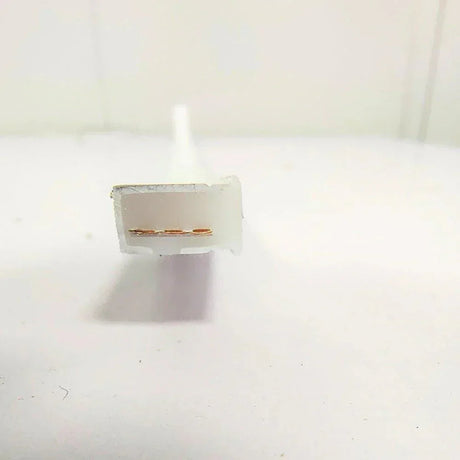

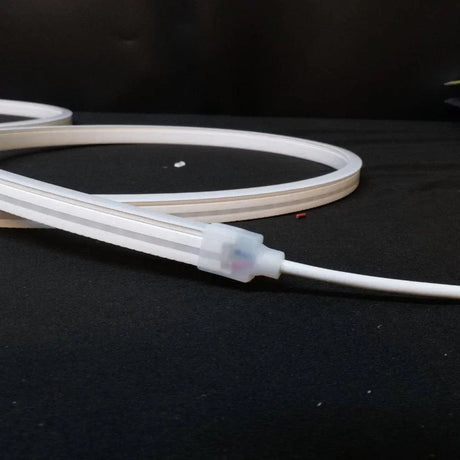

How should IP67 neon flex be terminated and sealed to avoid water entry at joints and end caps?

Fit correct end caps, apply recommended waterproof adhesive or silicone sealant, ensure cable glands are sealed, and allow full cure time never leave exposed copper or unsealed gaps at terminations.

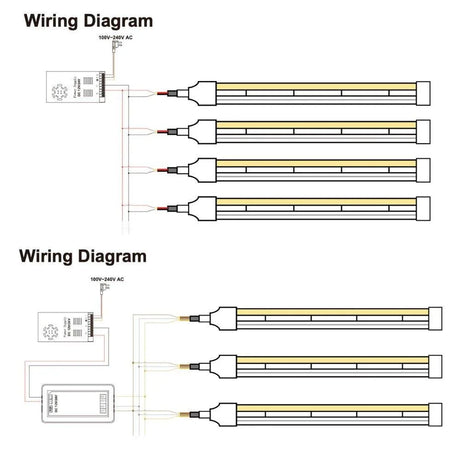

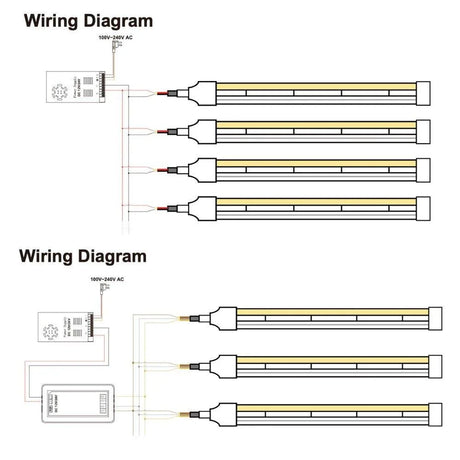

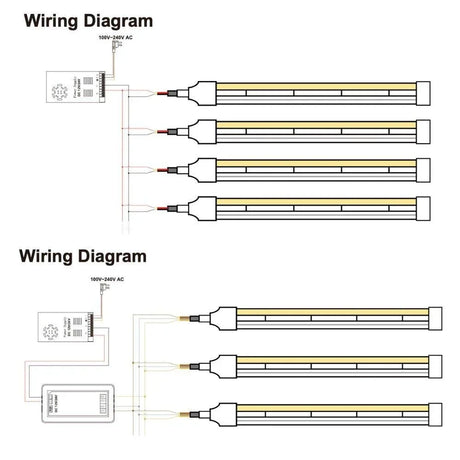

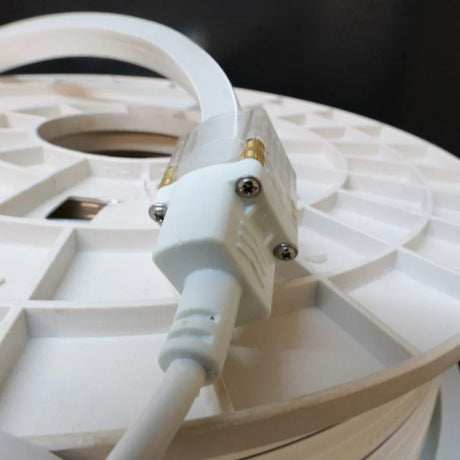

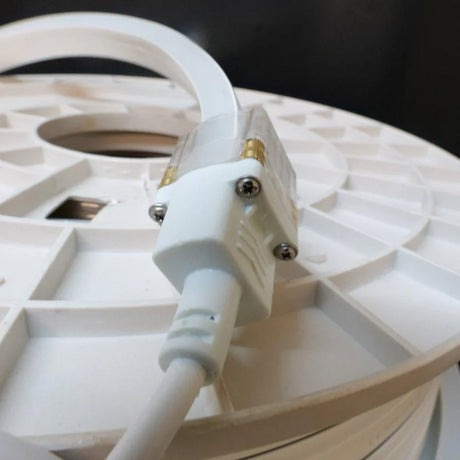

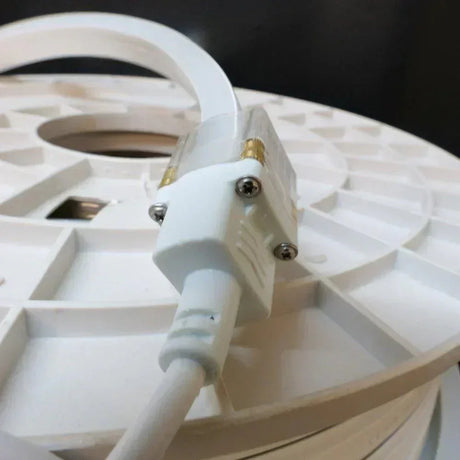

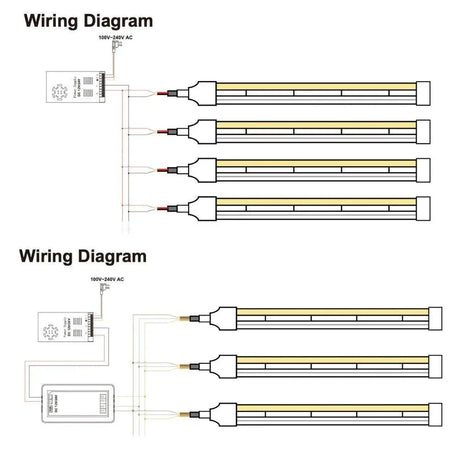

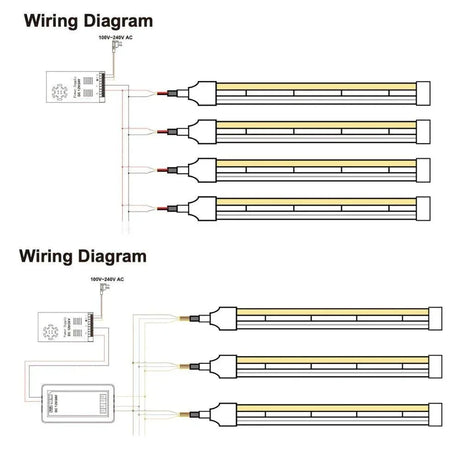

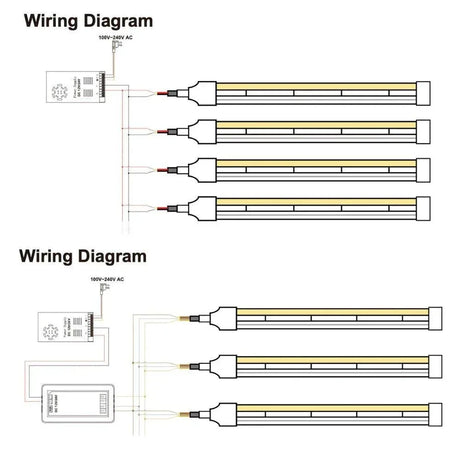

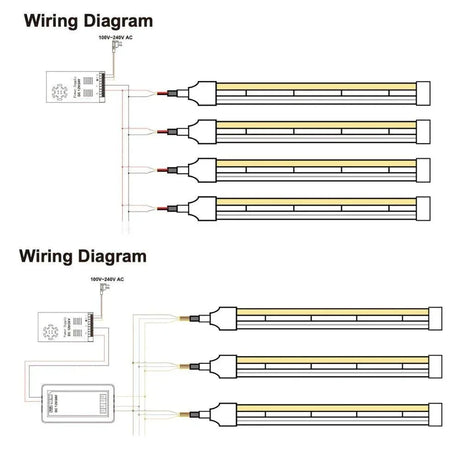

What cable types, connectors and power supplies are recommended to maintain an IP67 installation?

Use UV-resistant, tinned-copper cables, IP67/IP68-rated connectors and glands, and a weatherproof, adequately sized DC power supply installed in a ventilated IP-rated enclosure.

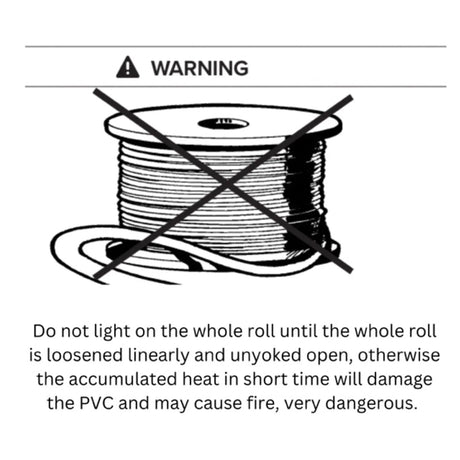

What are the most common installation mistakes with IP67 neon flex and how can they be avoided?

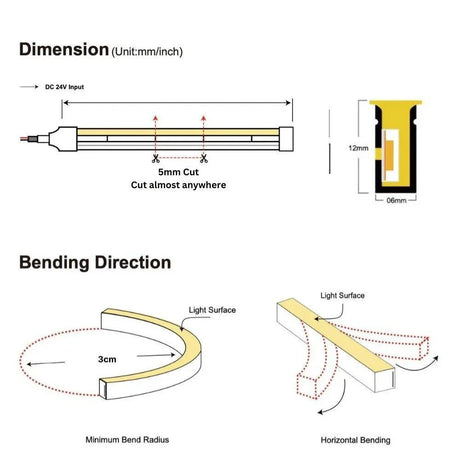

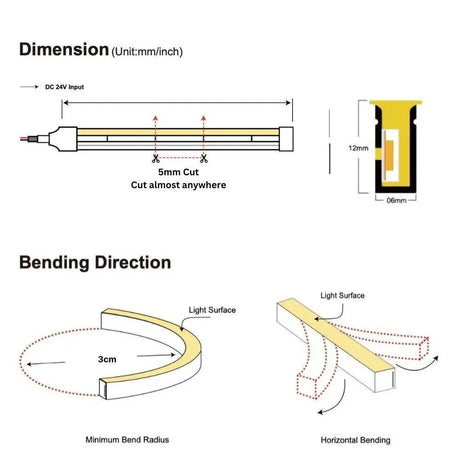

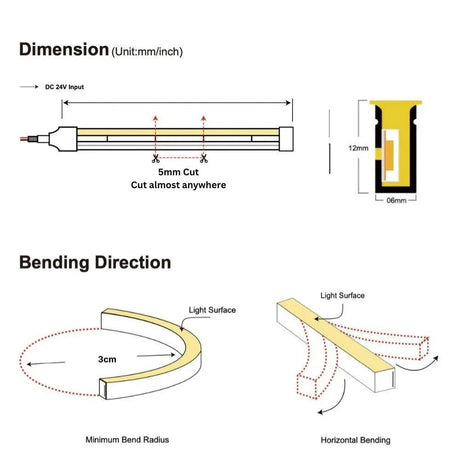

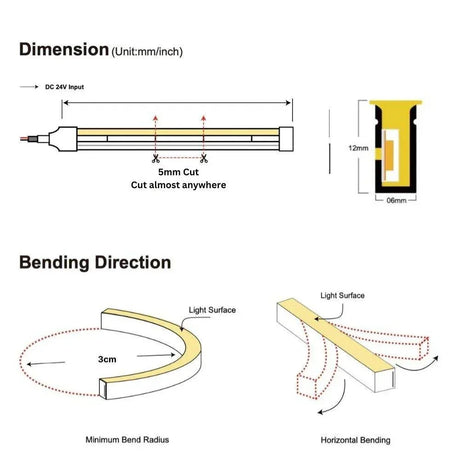

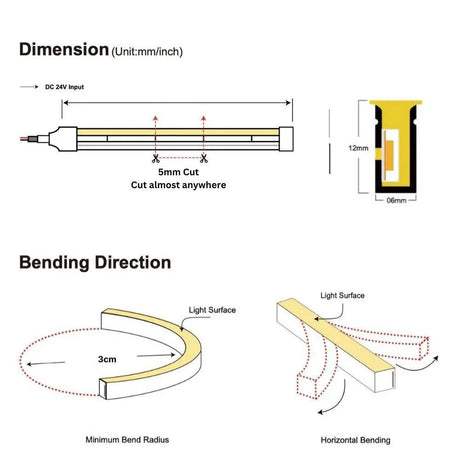

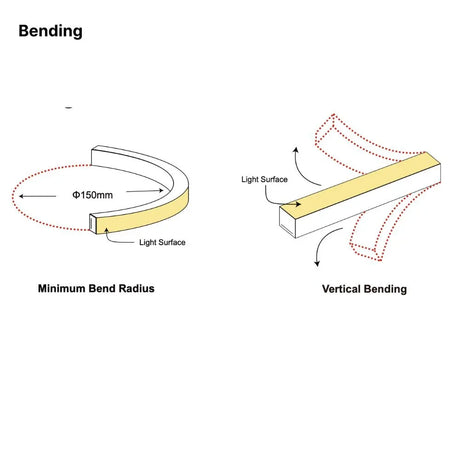

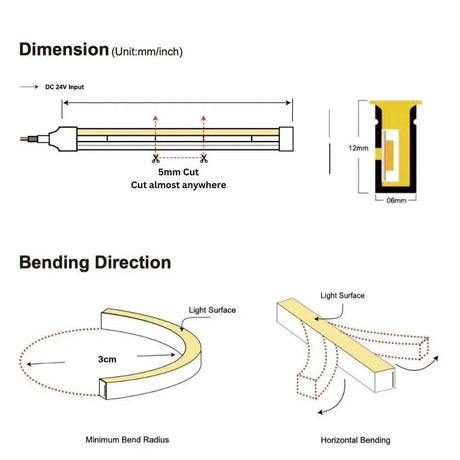

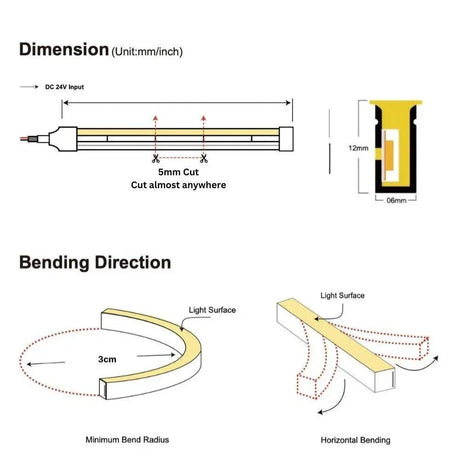

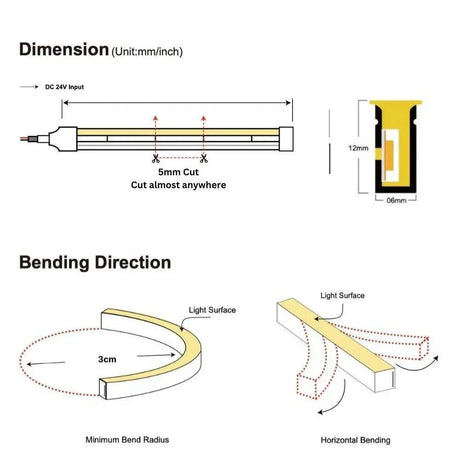

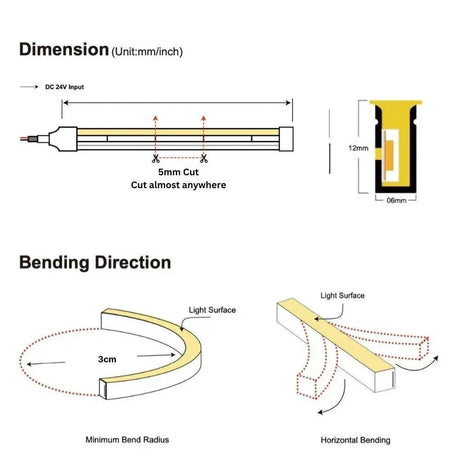

Common errors include poor end sealing, exceeding bend radius, and inadequate strain relief avoid them by following manufacturer termination procedures, using correct profiles/clips, and leaving expansion gaps.

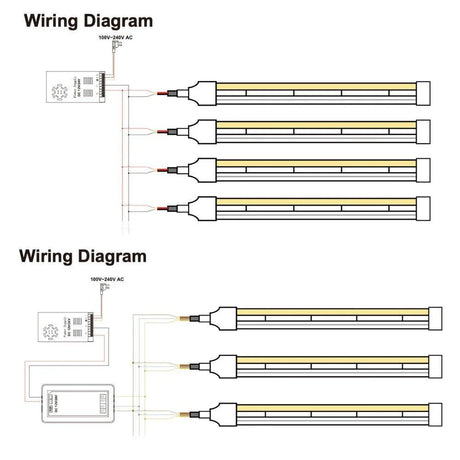

What is the maximum continuous run length for IP67 neon flex at 24 V?

Maximum continuous length varies by product and wattage, but many 24 V neon flex products support roughly 10–20 metres per continuous feed; for longer runs plan power-injection points or higher-voltage options.

How do I size the power supply for a long IP67 neon flex run (method)?

Multiply the neon flex’s watts per metre by the total length, then add 20–30% headroom for reliable continuous operation and to allow for voltage drop and inrush; choose a weatherproof PSU rated for that wattage.

Can IP67 neon flex be used for long continuous runs on roofs and parapets with 24 V?

Yes 24 V helps reduce current and voltage drop for longer runs, but you should still use trunk-and-branch feeds or periodic power injections to maintain even brightness across very long runs.

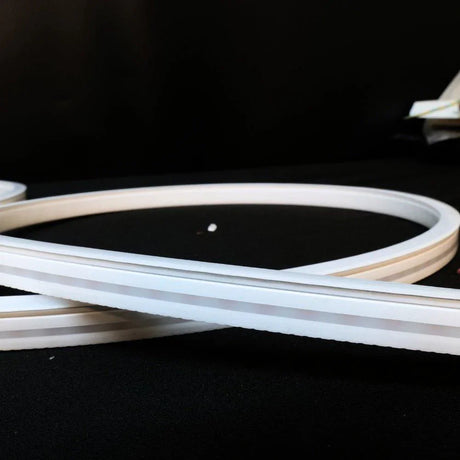

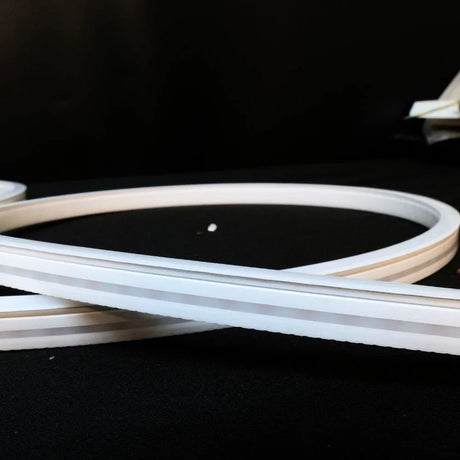

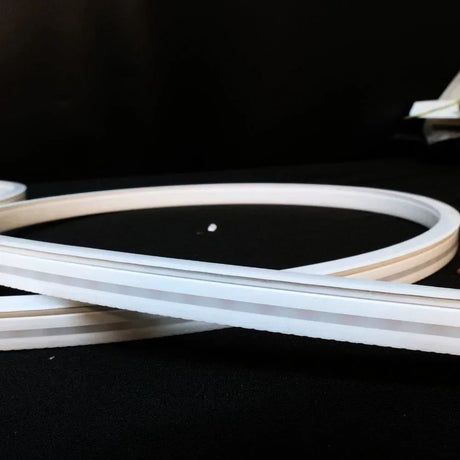

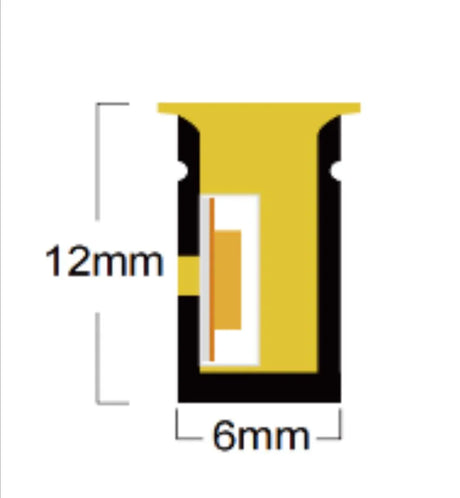

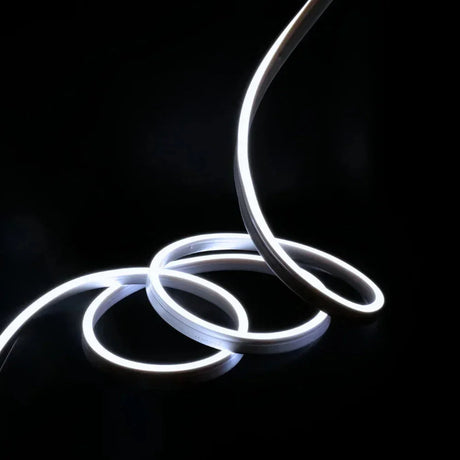

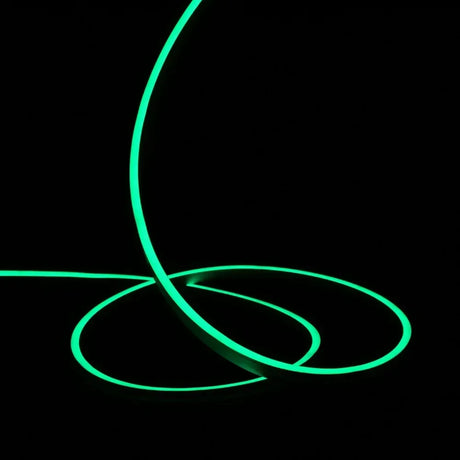

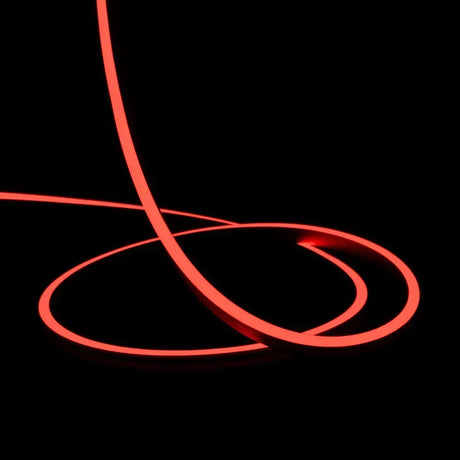

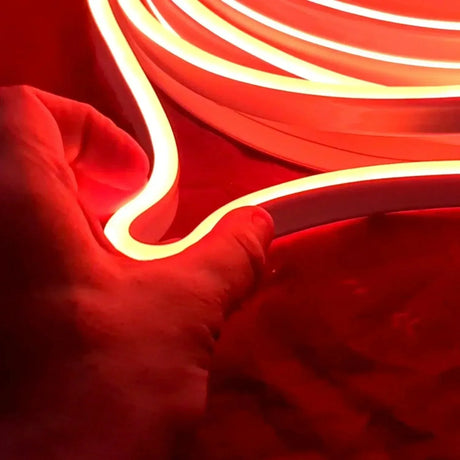

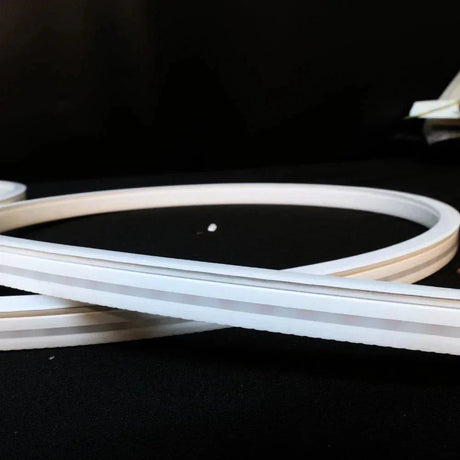

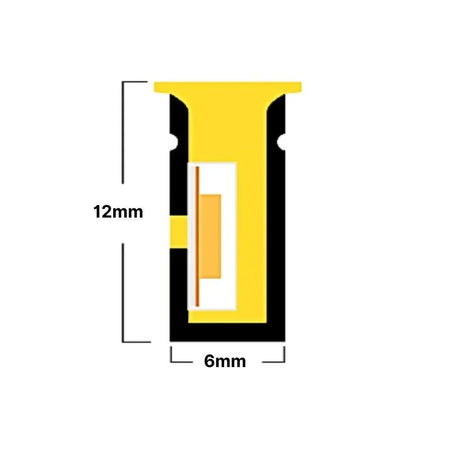

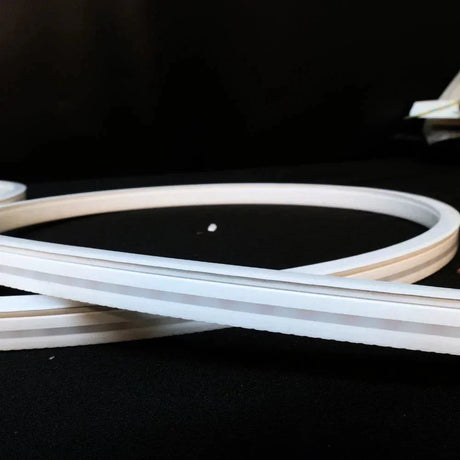

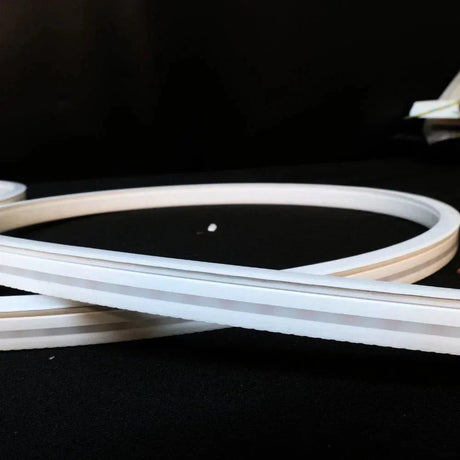

What profiles and bend directions work best for tight curves versus straight architectural lines?

Use shallow, flexible profiles or side-bend silicone jackets for tight curves and rigid aluminium channels with opal diffusers for long straight runs to optimize diffusion and heat dissipation; always respect the product’s specified bend radius.

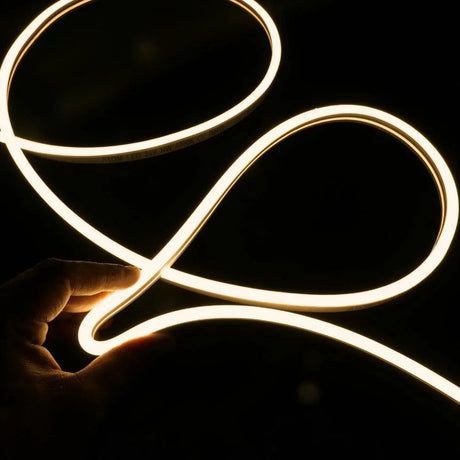

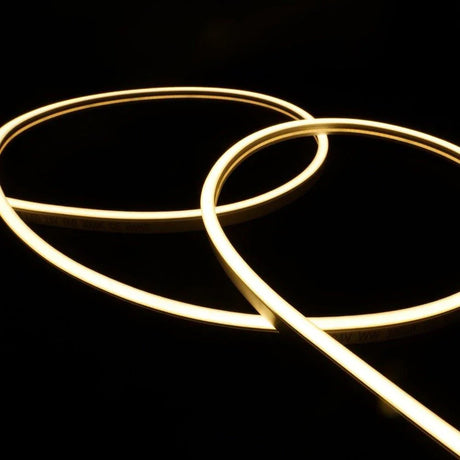

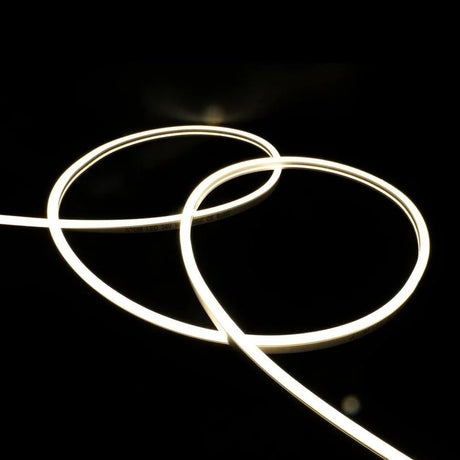

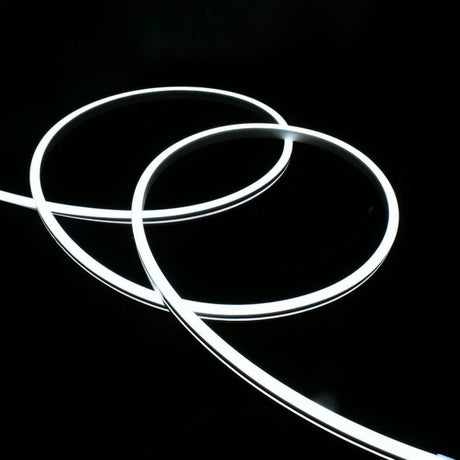

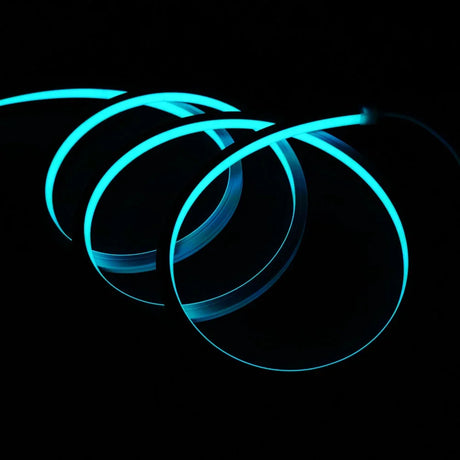

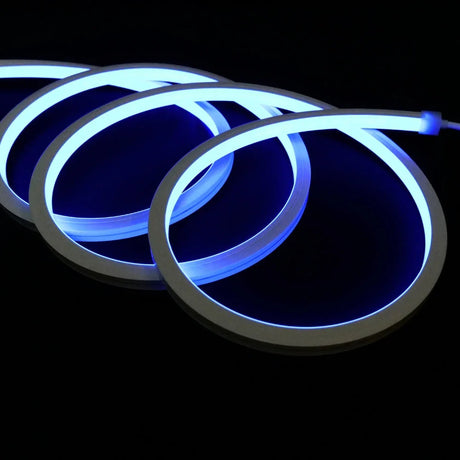

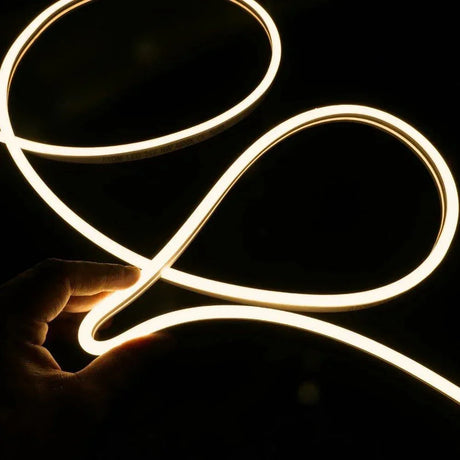

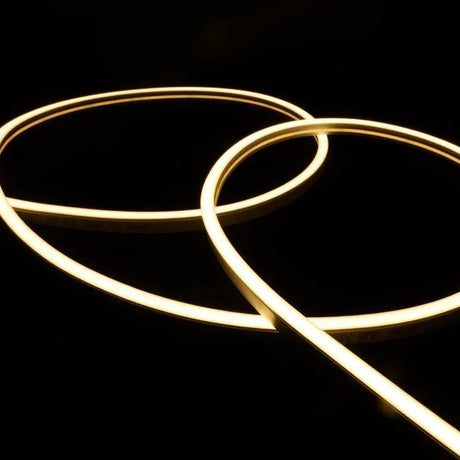

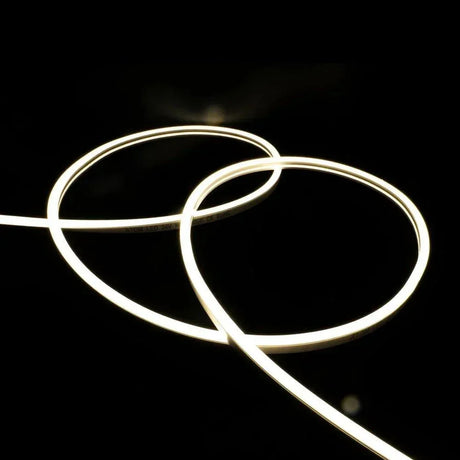

Why is IP67 neon flex a good choice for façade outlines, bridges, and signage?

Its sealed housing and robust materials deliver continuous, uniform illumination that withstands weather and mechanical stresses, making it ideal for visible architectural accents and outdoor signage.

How do UV exposure, temperature cycling and pollution affect IP67 neon flex lifespan?

UV, thermal cycling and airborne pollution can accelerate aging of lower-grade materials and seals; selecting UV-stabilized silicone and following best-practice installation reduces degradation and extends service life.

What cleaning and inspection routine is recommended for IP67 neon flex in outdoor installations?

Inspect seals, connectors and mounts at least annually (more often in harsh or coastal environments) and clean covers with mild soap and water to remove pollutants without damaging seals or coatings.

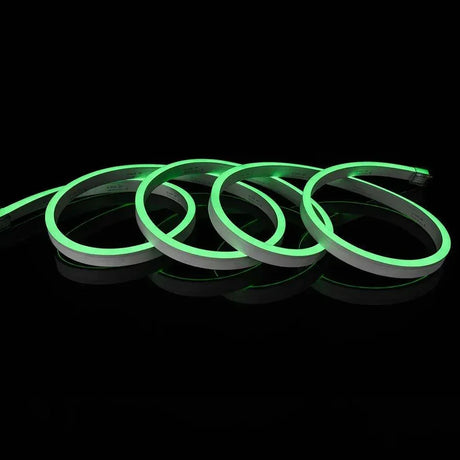

How does IP67 neon flex energy efficiency compare to traditional neon lighting?

LED neon flex uses significantly less power and emits less heat than glass neon, providing lower running costs and easier installation while delivering similar visual impact.

What specification checks and warranties should buyers look for when selecting IP67 neon flex?

Verify IP rating, lumen output (or lux per metre), CRI (if relevant), bend radius, UV stabilization, salt-air resistance, manufacturer warranty terms, and any certifications for outdoor/marine use.

When is IP67 sufficient and when should you choose IP68 instead?

Choose IP67 for rain-exposed façades, signage and splash-prone areas; upgrade to IP68 if the installation will be continuously submerged or regularly exposed to standing water.

How should you handle power-injection and voltage drop on long outdoor IP67 neon flex runs?

Calculate current per segment and inject power at regular intervals or use parallel feed trunks to minimize I²R losses; for long continuous layouts consider higher system voltages or distributed supplies to keep voltage stable.